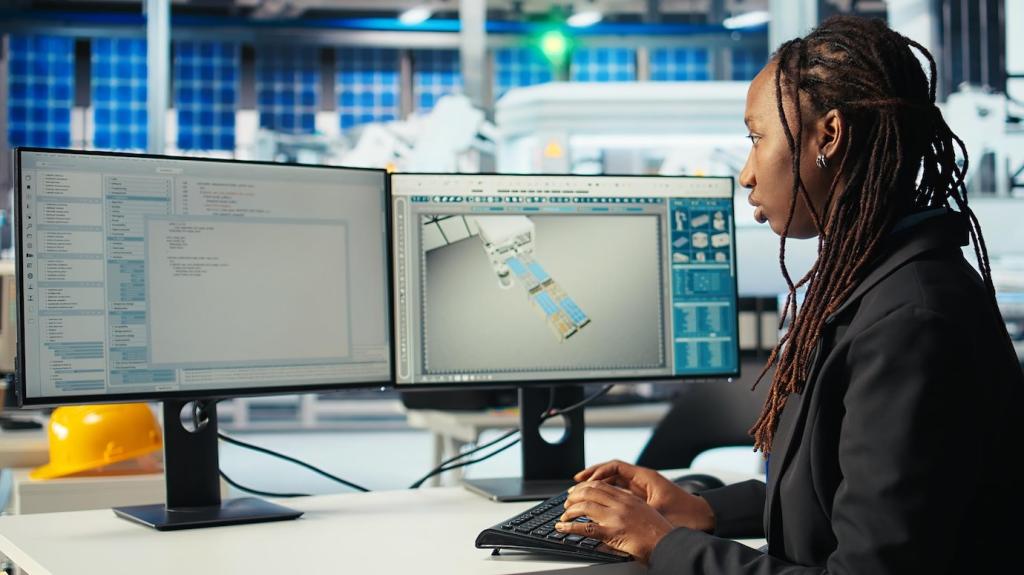

Why Renewable Resources Matter in Manufacturing

Natural resource constraints are tightening, yet renewable resources can replenish, rebuild soils, and promote biodiversity when sourced responsibly. Shifting from extraction to regeneration strengthens supply continuity and brand trust. Where are your biggest material risks today, and which renewable inputs could reduce exposure without compromising performance?

Why Renewable Resources Matter in Manufacturing

Manufacturers increasingly align with Science Based Targets, track Scope 1–3 emissions, and prioritize life cycle hot spots. Renewable energy and bio-based materials cut embodied carbon while improving disclosure under GHG Protocol. Which emissions metric matters most to your team, and how are you verifying reductions beyond marketing claims?